QUALIFIED TYRE RECYCLING COMPANY

THE

COMPANY

TPK's recycling activity is based on an advanced recycling plant for wasted tyres, completely computerized. The manufacturing process avoid any type of environment pollution and doesn't produce hamful industrial wastes.

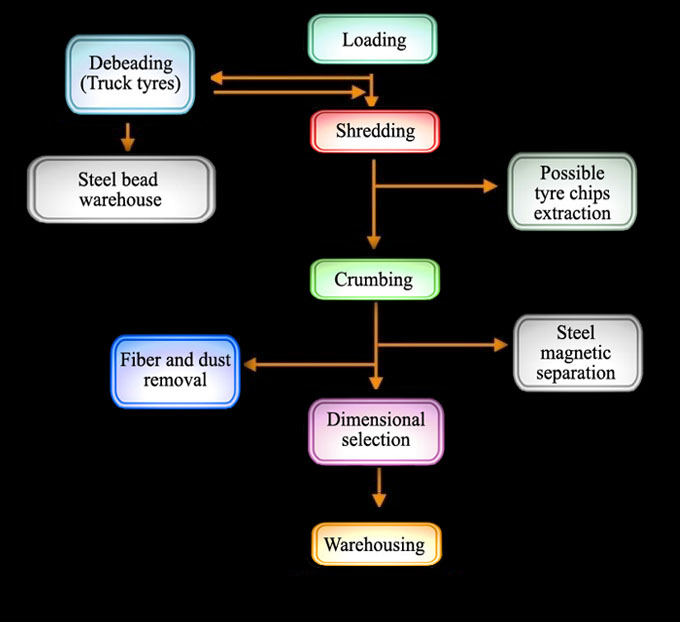

Recycling process must be divided into two stages: in the first step there's the warehouse of wasted tyres in the collection area; the second step consists in the recycling process, based on a mechanical manufacturing process, in which used tyres are shredded and subsequently crumbed, with separation of rubber, steel and fabric.

The final product is loaded according to crumb dimensions and dispatched towards other companies in order to produce new products.

AS A WASTE CAN BE TRANSFORMED INTO NEW RESOURCE

Scrap tyres come in the collection area and to be selected according to their typology (car tyres or truck tyres). This operation has become necessary since truck tyres, before any shredding operation, must be debeaded, to reduce wear and tear on the shredder and consecutive size reduction machines.

Tyre size reduction is obtained through a preliminary shredding process; at this step, if requested, tyre chips (approx 1" ÷ 2") are extracted and used as fuel in incineretor or in cement industry.

After preliminary shredding tyre chips, through a conveyor belt, enter in a granulator and reduced to a size smaller than 3/8” (10 mm). The granulator is contained into a soundproofed box.

Tyre granules comes to a vibrant plate that "opens" the material. Over this is placed a magnetic separator, equiped with a permanent magnet that attract steel filements, separated from rubber after the granulation step. The steel is finally packed into appropriate container.

In the final step rubber granules are submitted to a cleaning process that eliminates steel and fiber residuals and, thanks to the employment of two conveyors, final product will be stored in 2 m3 big-bags.

The industrial plant is equiped with many suction pipe and with a sophisticated filtering system that guarantees, for the air introduced in atmosphere, a percentage of dusts inferior than the quantity indicated in the rules in force.